Home > Press Release > First Demonstration of New Semiconductor Gallium Oxide (Ga2O3) Transistors

- A New Candidate for Next-generation Energy-saving Power Devices -

The National Institute of Information and Communications Technology (NICT, President: Dr. Hideo Miyahara), in collaboration with Tamura Co., Ltd. (Tamura, CEO: Naoki Tamura) and Koha Co., Ltd. (Koha, CEO: YasuhiroNakajima) has developed and tested the world's first single-crystal gallium oxide (Ga2O3) field-effect transistors.

Ga2O3 is a promising new semiconductor material for high-breakdown and low-loss power devices because of its excellent material properties, such as a wide bandgap, that can reduce the cost and energy consumption of mass produced devices. A feature of single-crystal Ga2O3 substrates is that they can be fabricated with the melt-grown method, and this is a great advantage of Ga2O3 over other widegap semiconductors such as SiC, GaN, and diamond for power device applications. We expect that the development of Ga2O3 power devices will not only contribute to solving global energy problems but also play an important role in the semiconductor industry in the near future.

Details of this achievement were published online in "Applied Physics Letters" on Jan. 4, 2012.

The search is on around the globe for innovative power saving technologies. In particular, widegap semiconductors such as SiC and GaN have the potential to be used in high-breakdown and low-loss power devices. We can expect that gallium oxide (Ga2O3) will be even more suitable than SiC and GaN for such applications because of its wide bandgap and other superior material properties. Another potential benefit is that single-crystal substrates of Ga2O3 can be mass-produced by using the melt-grown method. However, R&D on Ga2O3 electrical devices has lagged in spite of the material's high potential.

We fabricated a Ga2O3 metal-semiconductor field-effect transistor (MESFET) by using newly developed technologies for making single-crystal substrates, causing epitaxial growth, and fabricating devices. The most important point of this development is that we used a high-quality n-type Ga2O3 thin film on a single-crystal Ga2O3 substrate grown by molecular-beam epitaxy as a channel layer of the MESFET. The Ga2O3 MESFET exhibited excellent device characteristics including (1) an off-state breakdown voltage over 250 V, (2) an extremely low leakage current (several μA/mm), and (3) a high on/off drain current ratio of around 10,000. These excellent device characteristics would lead to a large reduction in power loss during the switching operation and would be suitable for making practical power devices.

This development of transistors using the widegap semiconductor Ga2O3 will pave the way for new high-performance power devices. We expect that R&D on Ga2O3 power devices will be a global concern. High-performance Ga2O3 power devices will contribute not only directly to the global energy savings but also to the economy of Japan by opening up new opportunities in the semiconductor industry. We expect that the devices will be used in many applications for which there are low and high breakdown fields.

Masataka Higashiwaki, Kohei Sasaki, Akito Kuramata, Takekazu Masui, and Shigenobu Yamakoshi, "Gallium oxide (Ga2O3) metal-semiconductor field-effect transistors on single-crystal β-Ga2O3 (010) substrates", Applied Physics Letters vol. 100, pp. 013504 (2012).

Appendix

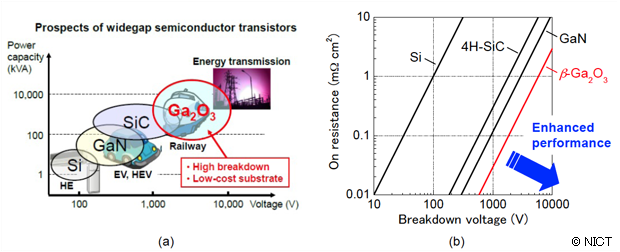

(a) Applications of semiconductor transistors in the near future

(b)Relationship between on-resistance and breakdown voltage of representative semiconductors and Ga2O3 for power devices

Figure 1(a) shows the prospects of other semiconductors and gallium oxide (Ga2O3), as estimated from their material properties. We expect that Ga2O3 power devices will initially have high-breakdown and high-power applications. Then as Ga2O3 devices become more popular, their applications will broaden to those of SiC and GaN by virtue of the easy and low-cost substrate production.

Figure 1(b) shows that the material has better power device performance toward the bottom-right corner of the graph. Two parameters, "breakdown voltage" and "on-resistance", determine power device performance, are in a trade-off relation anytime. Thus, the straight lines in Fig. 1(b) show the ideal performance limits of the materials. We can see from this estimate that Ga2O3 has better characteristics as a power device material than not only Si but also SiC and GaN.

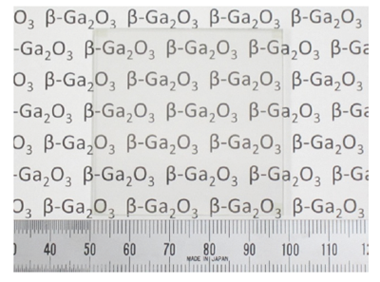

Figure 2 shows a photograph of a two-inch square single-crystal β-Ga2O3 substrate fabricated from melt. The melt-grown method is a low-energy-consumption, low-cost way to make large wafers because it does not need a high-temperature and/or high-pressure environment and its material efficiency is high. The method is especially suitable for mass production. The ability to fabricate single-crystal substrates is a big advantage of Ga2O3 for industry because other widegap semiconductors (SiC, GaN, and diamond) cannot be made in this way.

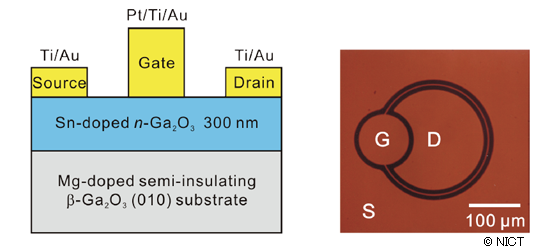

Figures 3(a) and (b) show a schematic cross-sectional illustration and a micrograph of a fabricated Ga2O3 MESFET. We used newly developed Ga2O3 single-crystal substrate, epitaxial thin film growth, and device-process techniques to fabricate the device.

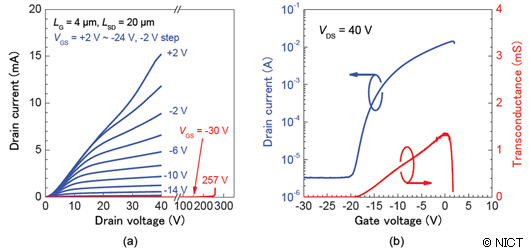

Figure 4(a) shows the output characteristics of the Ga2O3 MESFET. We obtained complete on/off control of the drain current by using the gate voltage swing. Furthermore, the off-state breakdown voltage was over 250 V, a very high value considering the fact that the device has a simple FET structure without any measures to increase the breakdown voltage.

As shown in Fig. 4(b), the off-state drain leakage current is very small (a few μA), and it results in a high on/off drain current ratio of about 10,000. The low leakage current at the off state directly leads to a decrease in power loss. These device characteristics obtained at the early stage of development indicate the great potential of Ga2O3-based electrical devices for future power-device applications.

Technical Contact

Terahertz and Millimeter wave ICT Laboratory

Advanced ICT Research Institute

Tel: +81-42-327- 6092

E-mail:

Media Contact

Public Relations Department

Tel: +81-42-327-6923

E-mail: