Highlights

-

Development of the world's first practical surface-emitting laser suitable for optical fiber communications systems.

-

Utilization of quantum dots as an optical gain medium, enabled by NICT's high-precision crystal growth technology and Sony's advanced processing technology.

-

A significant advancement toward miniaturization, reduced power consumption, and cost efficiency of light sources used in optical fiber communication systems.

The National Institute of Information and Communications Technology (NICT, President: TOKUDA Hideyuki Ph.D.), in collaboration with Sony Semiconductor Solutions Corporation (Sony), has developed the world's first practical surface-emitting laser that employs quantum dot(QD) as the optical gain medium for use in optical fiber communication systems.

This achievement was made possible by NICT's high-precision crystal growth technology and Sony's advanced semiconductor processing technology. The surface-emitting laser developed in this study incorporates nanoscale semiconductor structures called quantum dots as light-emitting materials. This innovation not only facilitates the miniaturization and reduced power consumption of light sources in optical fiber communications systems but also offers potential cost reductions through mass production and enhanced output via integration.

The results of this research were published in Optics Express, a leading international journal in optical technology, published by the OPTICA Publishing Group in the United States, in Vol. 33, Issue 6, on Monday, March 24, 2025.

Background

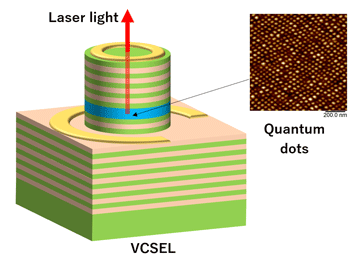

Figure 1. Schematic of a surface-emitting laser and guantum dots.

Modern communication technologies require large-capacity data transmission with minimal power consumption. Vertical-cavity surface-emitting lasers (VCSELs) have attracted significant attention as a key technology that addresses these requirements, particularly in optical communications. However, VCSELs typically operate in the near-infrared region, at wavelengths of 850 or 940 nm. Developing VCSELs that operate at the long wavelength of 1,550 nm—typically used in existing optical fiber communications—presents significant technical challenges. This challenge results from the increased complexity in both material selection and structural design for long-wavelength VCSELs than those of short-wavelength VCSELs. In addition, achieving high output and efficiency in VCSELs at 1,550 nm, it is necessary to develop a material or device structure that emits efficiently.

Achievements

In a joint research project with Sony, NICT achieved the world's first electrically driven VCSEL operating at 1,550 nm—the standard wavelength for optical fiber communication—using nanoscale semiconductor structures known as quantum dots as the optical gain material (see Figure 1).

NICT developed the first core technology: a high-precision crystal growth method for compound semiconductors using molecular beam epitaxy. Fabricating a VCSEL requires growing a highly reflective semiconductor multilayer film (DBR: Distributed Bragg Reflector) to enhance light intensity; however, fabricating DBRs that operate at 1,550 nm has been challenging because the combination of materials that can be grown is limited. In this study, we developed a technology that can precisely grow DBR by strictly controlling the ratio of materials in the crystal growth and realized a semiconductor DBR with a high reflectivity exceeding 99% even at 1,550 nm. In addition, strain-compensation techniques were applied to the VCSEL production to accurately cancel the internal crystal strain (strain generated within the material) that occurs around the quantum dots, thereby significantly increasing the density of the quantum dots and improving the light-emitting performance.

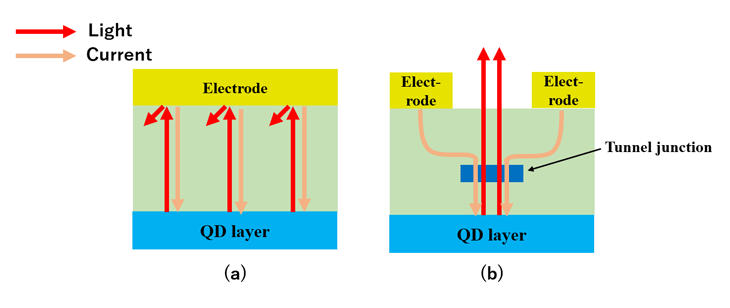

Sony contributed to the second core technology: a device design and fabrication process that enables highly efficient current injection employing a structure called a tunnel junction. VCSELs emit light perpendicular to the wafer surface; therefore, even if quantum dots emit light, conventional electrode placement obstructs light extraction. Sony addressed this by implementing a tunnel junction structure that permits efficient current flow while facilitating light extraction employing a precise device process.

Through the integration of these two technologies, we succeeded in lasing VCSELs using quantum dots at 1,550 nm as a light-emitting material with a small current of 13 mA (low threshold). Furthermore, polarization fluctuations were eliminated, resulting in a stable output.

VCSELs employing quantum dots as optical gain materials, exhibit excellent temperature stability. In addition, VCSELs exhibit scalable structures that enable mass production. These characteristics are expected to enable higher performance, reduced cost, and higher output via the integration of optical communication wavelength-band lasers.

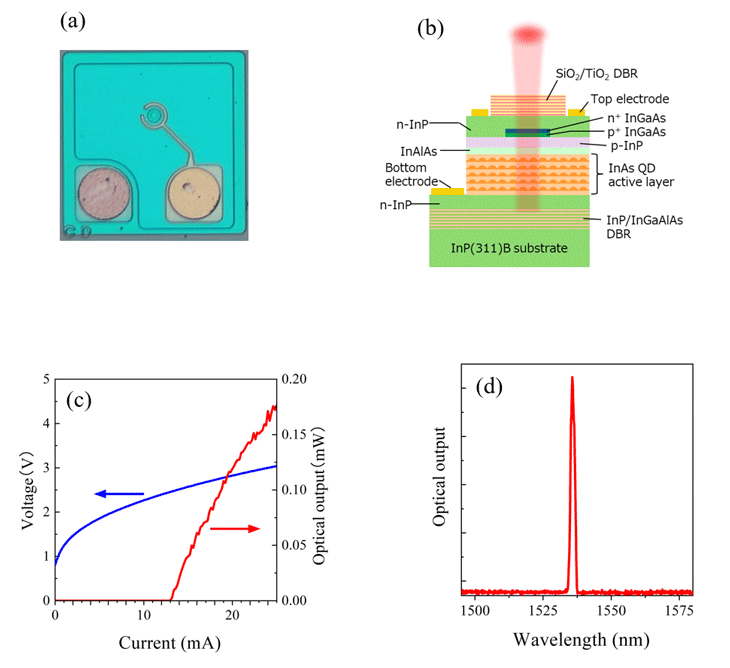

Figure 2 (a) Micrograph of the quantum dot-based VCSEL that was fabricated,

(b) Schematic of the cross-sectional structure of the quantum dot-based VCSEL,

(c) Current-light output characteristics (red) and current-voltage characteristics (blue), (d) Laser oscillation spectrum of the VCSEL.

(b) Schematic of the cross-sectional structure of the quantum dot-based VCSEL,

(c) Current-light output characteristics (red) and current-voltage characteristics (blue), (d) Laser oscillation spectrum of the VCSEL.

Future Prospects

We aim to conduct advanced technical studies on quantum-dot-based VCSEL technology to further enhance the capacity and reduce power consumption in optical fiber communication systems beyond the 5G era. Concurrently, we will undertake efforts to promote social deployment of this technology.

The paper detailing the experimental results was accepted for publication in Optics Express, a leading international journal on optical technology, published by the OPTICA Publishing Group in the United States, and appeared in Vol. 33, Issue 6, on Monday, March 24, 2025 (local time).

Role of each organization

NICT: Highly reflective semiconductor multilayer fabrication and quantum dot crystal growth technology.

Sony: Device design for the entire VCSEL structure and device process technology.

References

Authors: MICHINORI SHIOMI, HARUKI KISHIMOTO, TOMOMASA WATANABE, MASAYUKI TANAKA, DAIJI KASAHARA, HIROSHI NAKAJIMA, MASASHI TAKANOHASHI, RYOJI ARAI, YUTA INABA, YUDAI YAMAGUCHI, YUYA KANITANI, YOSHIHIRO KUDO, MIKIHIRO YOKOZEKI, NORIYUKI FUTAGAWA, KOUICHI AKAHANE, AND NAOKATSU YAMAMOTO

Title: Electrically pumped laser oscillation of C-band InAs quantum dot vertical cavity surface-emitting lasers on InP(311)B substrate

Journal: Optics Express Vol. 33 Issue 6 pp. 12982-12988

DOI: 10.1364/OE.551300

nict.go.jp

nict.go.jp