FFPA Completes Technical Specifications to Stabilize Various Wireless Communication Systems Co-located in Factory Sites.

- A progress toward visualization and integrated management of various information -

September 24, 2019

National Institute of Information and Communications Technology

Flexible Factory Partner Alliance

- FFPA has completed the technical specifications to stabilize various wireless communication systems for factories.

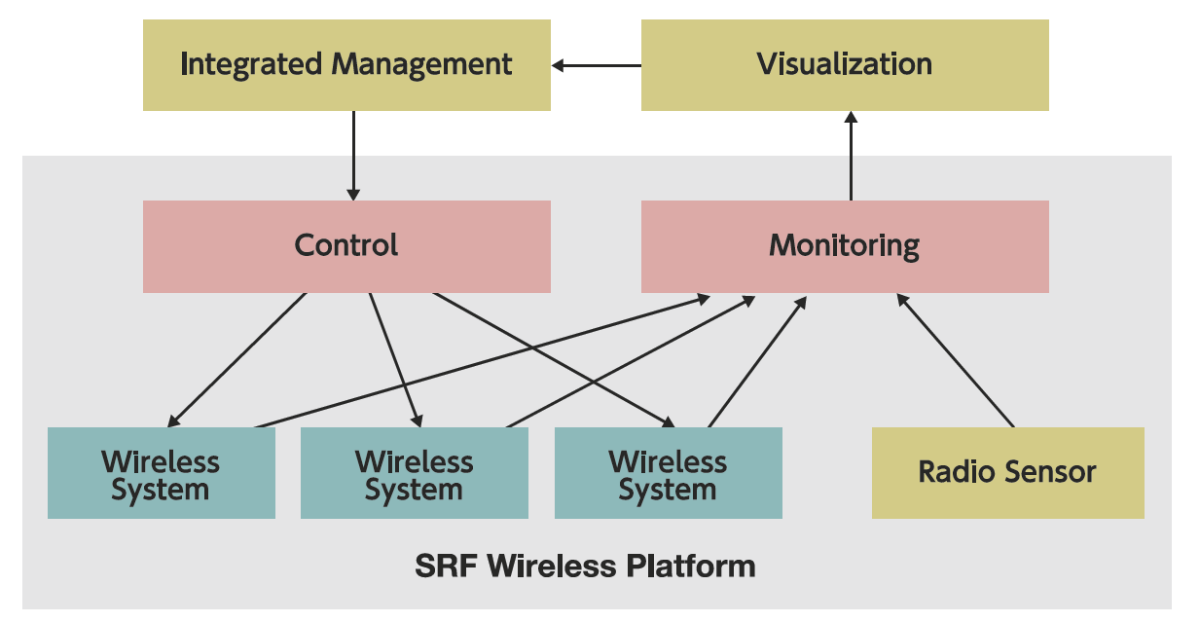

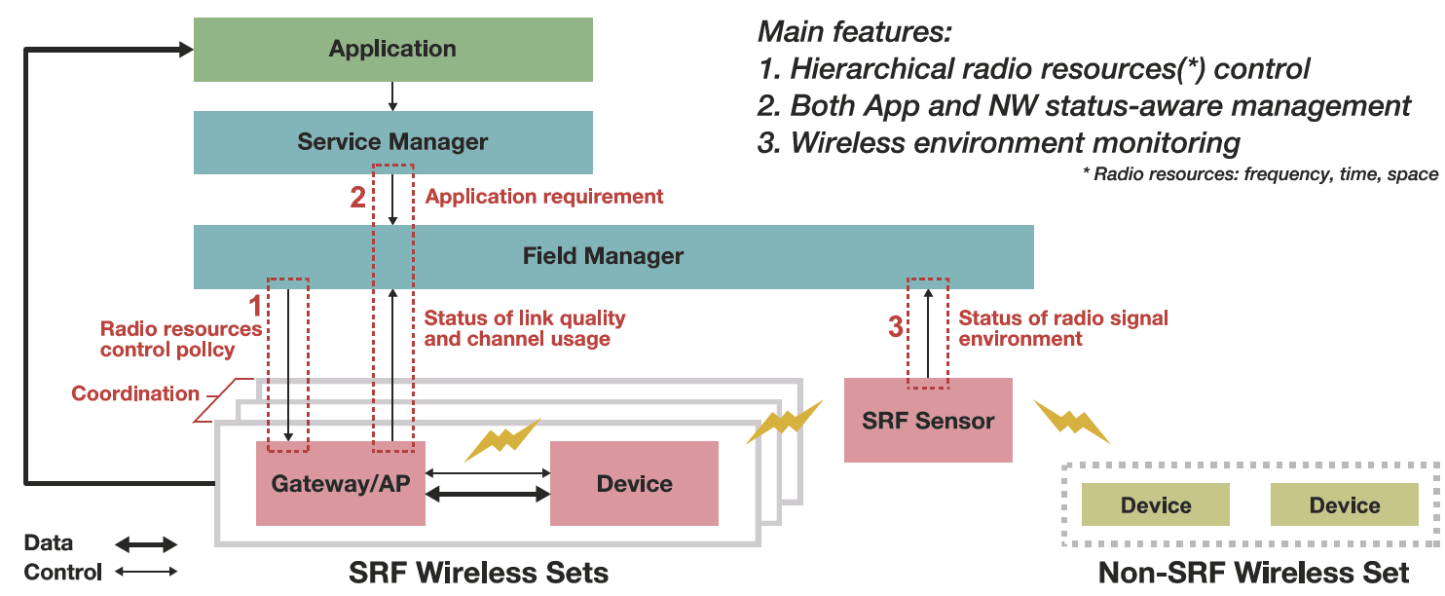

- NICT has contributed architecture named Smart Resource Flow (SRF) wireless platform to the specifications.

- Adoption of the platform enables stable wireless communications and visualization and integrated management of various information on the manufacturing sites.

Background

Achievements

The features are:

Future Prospects

About Flexible Factory Partner Alliance (FFPA)

Glossary

Contact

Hajime Koto

Secretary-General

Flexible Factory Partner Alliance

E-mail:

Satoko Itaya

Wireless Systems Laboratory

Wireless Networks Research Center

NICT

E-mail: