A New Architecture for Miniaturization of Atomic Clocks Exploiting a Piezoelectric-Thin-Film Vibration

- From a rack-mount system toward a microchip -

January 23, 2018

National Institute of Information and Communications Technology

Tohoku University

Tokyo Institute of Technology

Highlights

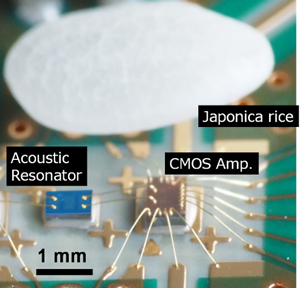

- Piezoelectric-thin-film vibration exploited to miniaturize an atomic clock

- Frequency instability and 30% reductions in chip area and 50% reduction of power consumption

- High-end frequency standards would be incorporated into wireless devices like smartphones

Background

Achievements

[Click picture to enlarge]

Future Prospects

Supplementary Information

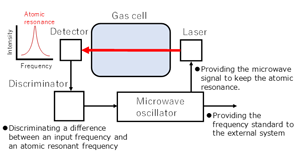

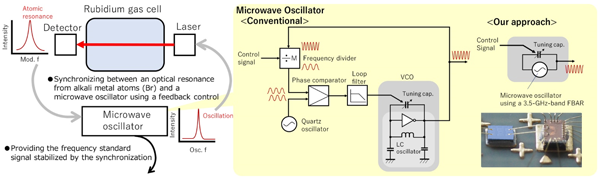

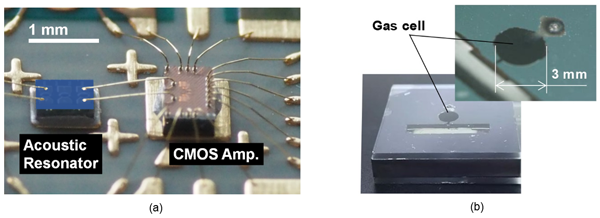

Overview of the Atomic Clock System

(b) A micromachined Rb gas cell

[Click picture to enlarge]

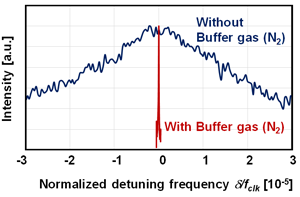

*fclk: A clock transition frequency of 87Rb

Glossary

Atomic Clock

Frequency Multiplication

Piezoelectric Thin Film

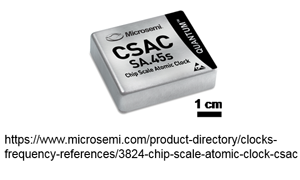

Module-Sized Atomic Clock

It is an atomic clock module using the Coherent Population Trapping (CPT) spectrum to optically interrogate the electron transition with ease. This module was developed in the US, and has begun to be used in some oceanographic surveys.

Rubidium

MEMS: Micro-Electromechanical System

Technical Contact

Motoaki Hara

Space-Time Standards Laboratory

Applied Electromagnetic Research Institute

NICT

Tel: +81-42-327-5476

E-mail:

Takahito Ono

Department of Mechanical System Engineering

Graduate School of Engineering

Tohoku University

Tel: +81-22-795-5806

E-mail:

Hiroyuki Ito

Laboratory for Future Interdisciplinary Research of Science and Technology (FIRST)

Institute of Innovative Research (IIR)

Tokyo Institute of Technology

Tel: +81-45-924-5010

E-mail:

Media Contact

Sachiko Hirota

Press Office

Public Relations Department

NICT

Tel: +81-42-327-6923

Fax: +81-42-327-7587

E-mail:

Hiroko Banba

Press Office

Graduate School of Engineering

Tohoku University

Tel/Fax: +81-22-795-5898

E-mail:

Public Relations Section

Tokyo Institute of Technology

Tel: +81-3-5734-2975

E-mail: