Successful Experiment with Stabilization Technology for Wireless Communications for Manufacturing Systems

– Realizing a "non-stop line" with wireless visualization and coordinated control of different systems -

February 18, 2021

(Japanese version released on November 25, 2020)

National Institute of Information and Communications Technology

Abstract

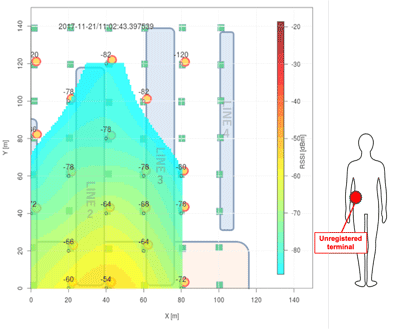

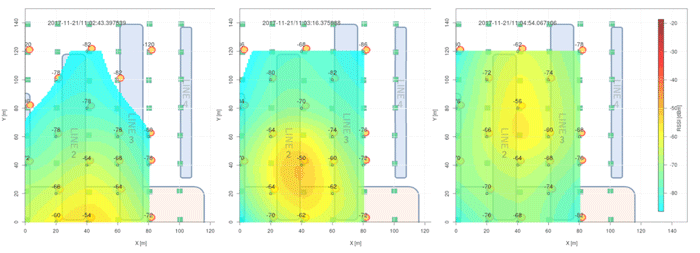

- Test at TOYOTA Takaoka Plant: Verification of the wireless environment real-time visualization technology developed by NICT can be carried out on the actual assembly line in operation, and we confirmed that unregistered terminals can be detected before affecting the wireless system on the production line.

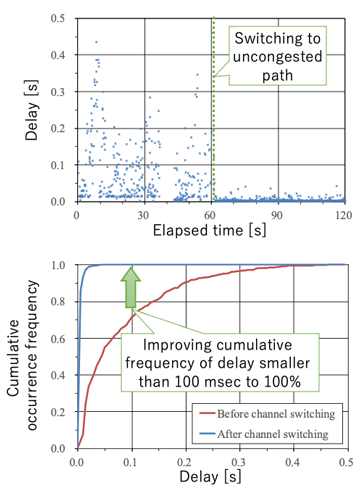

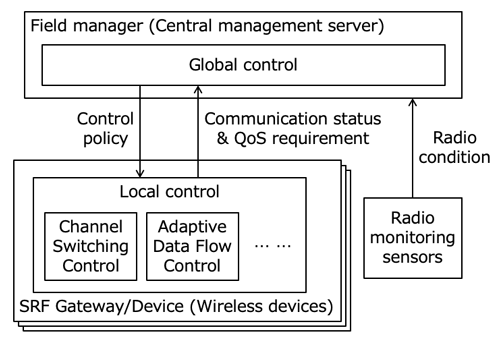

- Test at TOYOTA Motomachi Plant: We verified the SRF wireless platform that enables stable wireless communication through coordinated control between different wireless communication systems developed by NICT. As a result, we were able to confirm the effectiveness of this platform, such as establishing an appropriate communication route according to the degree of wireless congestion.

Background

Achievements

Upper figure: Time change of delay.

Lower figure: Frequency of delay occurrence.

Future Prospects

Appendix

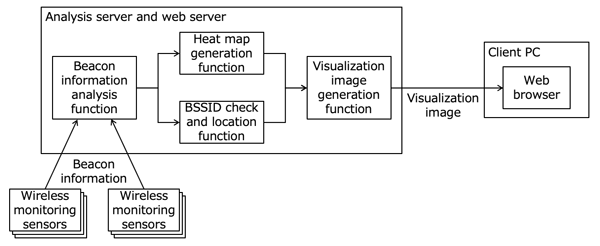

1. Real-time visualization technology for wireless environment

2. SRF wireless platform

Glossary

Technical Contact

ITAYA Satoko

Wireless Systems Laboratory

Wireless Networks Research Center

E-mail:

Media Contact

HIROTA Sachiko

Press Office

Public Relations Department

E-mail: